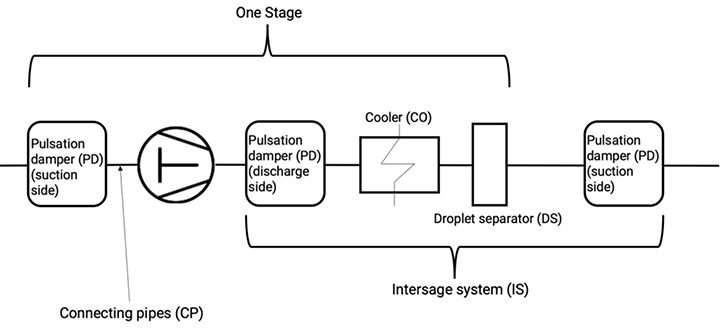

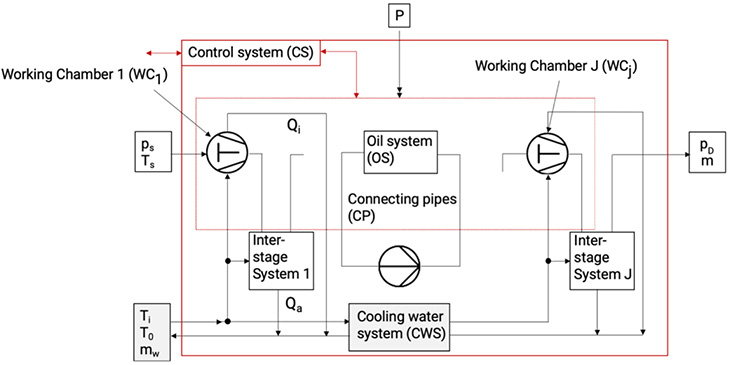

Compressor stations consist of a compressor and different other components, which are necessary for their operation.

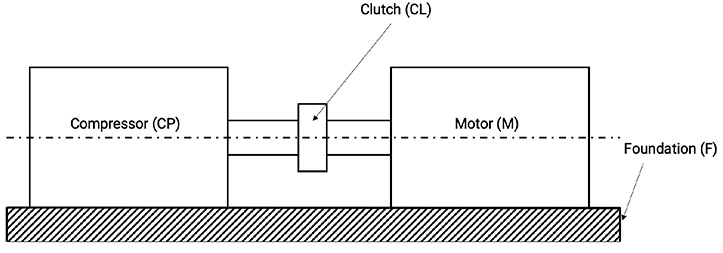

The motor M is usually an electric motor and is connected to the compressor CP via the clutch CL. The compression unit is represented by the compressor and the motor. It is installed on a common foundation F, see Figure 2.3. In a machine dynamic sense, that is in relation to variations in compressor speed, foundation stresses and vibrations, the compressor station has to be considered as a unit.