Usually, piston rings touching the cylinder wall do the sealing of the piston against the non-moving cylinder wall [17]. These can be lubricated or non-lubricated (also called dry-running).

Lubricated piston rings are made of a special type of cast iron. Materials for non-lubricated piston rings are fluoropolymers (e.g. PTFE), polymer blends (blends of various polymers) and high-temperature polymers (e.g. PEEK).

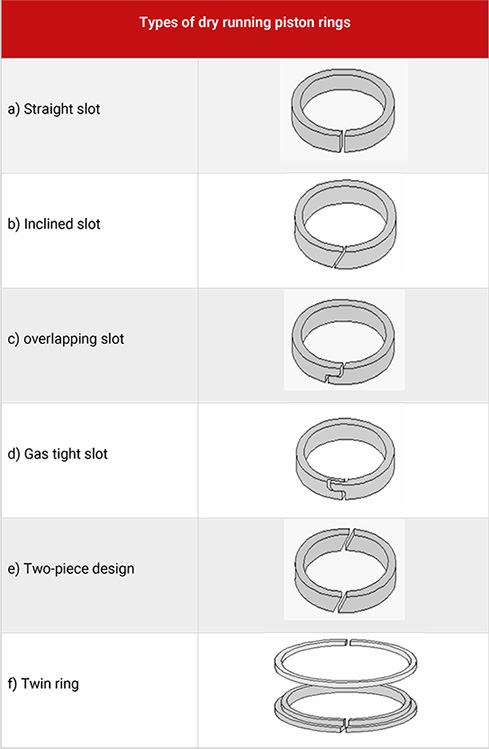

In special cases, labyrinth seals are used, which run without touching the cylinder walls. For dry-running piston rings various types of cuts were developed, which enable the smallest possible increase in leakage with wear. Especially the double overlapping (gas tight) gap and the twin ring system are of advantage in this respect. However, with brittle ring material, the design has to be such that the gap is not liable to fracture, see Table 4.10.