In order to evaluate the energetic quality of a compressor (as with all energy machines) an efficiency is calculated. With piston compressors also a volumetric efficiency is being used, which is defined as the useable part of the piston displacement for gas delivery…

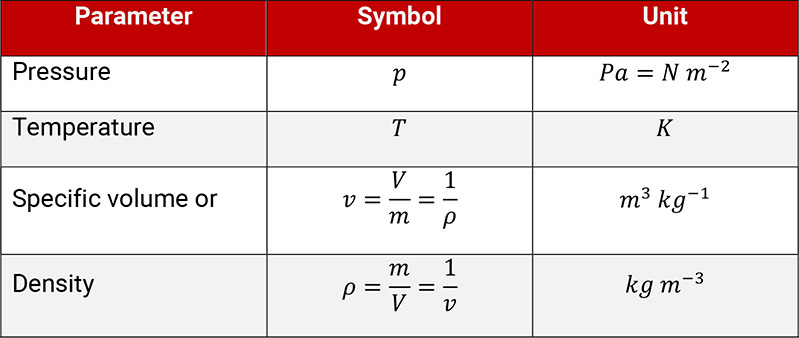

- Introduction to Thermodynamics

This section is meant for those readers, who have no basic knowledge of thermodynamics so far, but who would like to be able to follow the thermodynamic considerations in the following chapters. For further information on thermodynamics we recommend for example [2].

- Compressors

Compressors are machines, which increase the pressure of a gas through input of mechanical work… - Reciprocating compressors

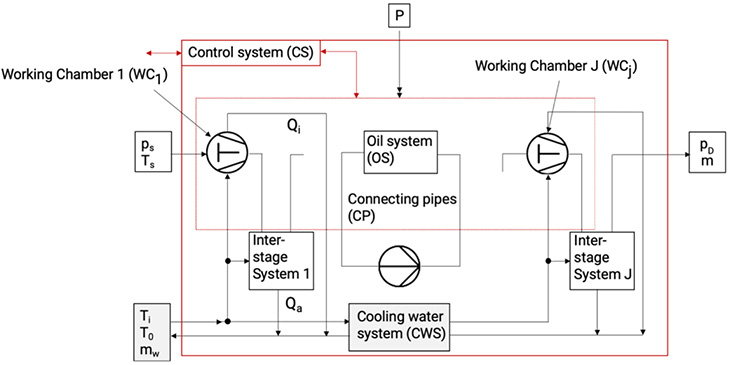

Reciprocating compressors work according to the positive displacement principle… - Compressor station

Compressor stations consist of a compressor and different other components, which are… - Pumping duties

Compressors are chosen or developed according to their defined pumping duty…

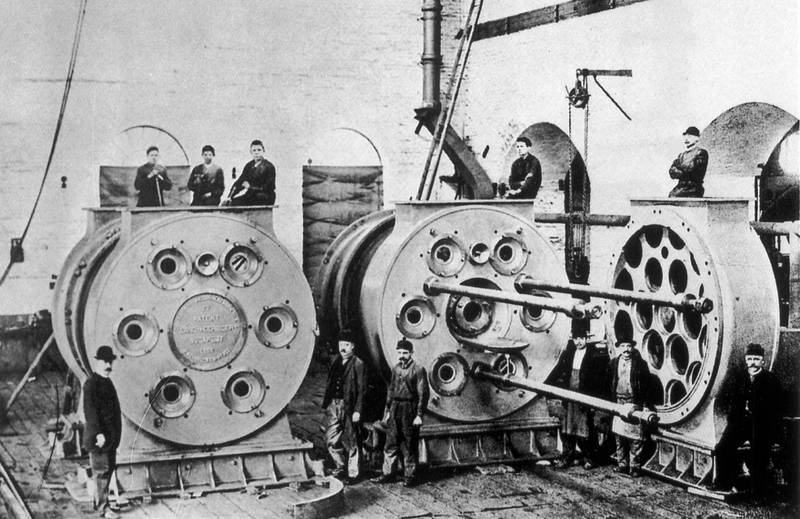

- History and development

Pressure increase of air by applying mechanical work had already been done in early times. In the middle ages hand operated bellows were used in metal foundries… - Process and natural gas compressor

Process compressors used in the process industry (for example in the liquification, rectification and with chemical reaction of technical gases) have to fulfil demanding requirements in relation to performance and reliability… - Air and refrigeration compressors

Whilst stationary compressors for air are carried out in increasing numbers as screw compressors, air compressors for road vehicles are still being developed in the plunger type design…

- Drive mechanism

The driving gear of the compressor converts the rotating motion of the crank into the oscillating motion of the piston and also transmits work… - Cylinders

Cylinders comprise the working chambers, the compressor valves and the cylinder cooling. The design of the cylinder is adapted to the specific pumping duty…

- Interstage systems

For the interstage and final cooling in piston, compressors have to fulfill specific requirements… - Compressor valves

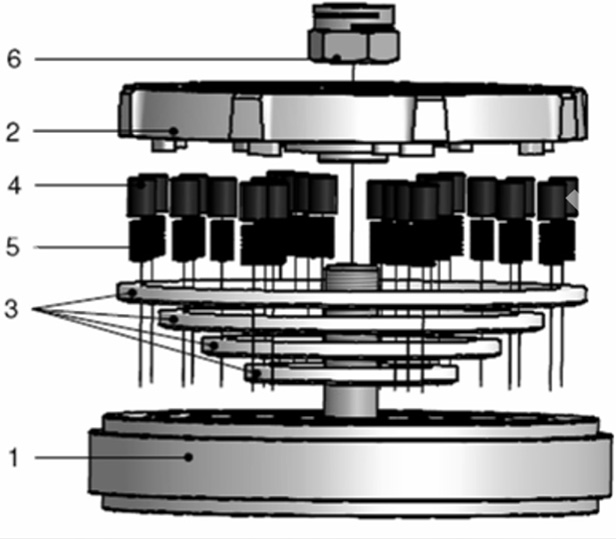

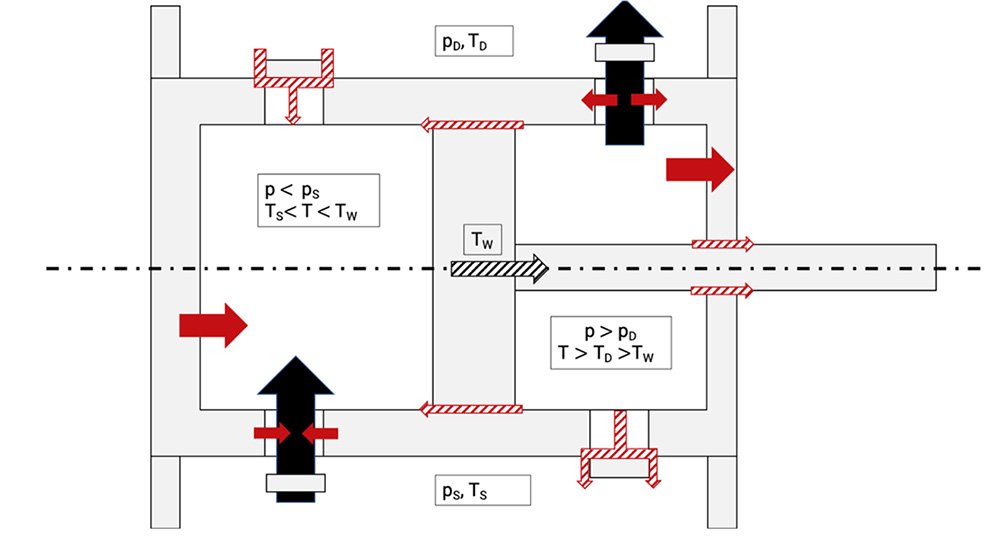

The gas flow in and out of the cylinder is controlled by self actuated, that is gas pressure controlled in- and outlet valves (suction and discharge valves)… - Piston rings and packings

The sealing of the piston against the non moving cylinder wall is done usually by piston rings touching the cylinder wall…

- Processes in the working chamber

An approximate calculation of the working cycle for a specific cylinder of your choice can be carried out with the program… - Flow through the stage

The quasi stationary changes in the conditions of state of the gas when flowing through a compressor stage can be represented in a T,s- diagram… - Efficiency of compressors

- Characteristic diagrams

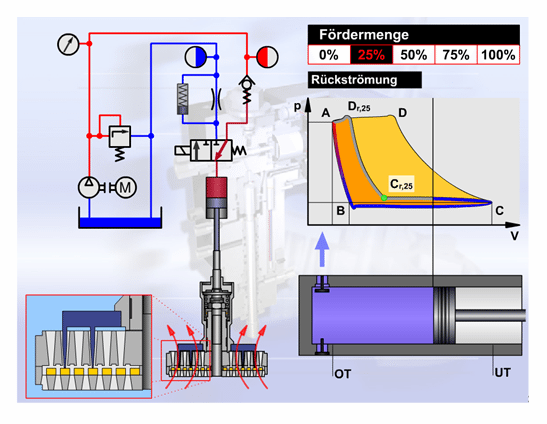

Characteristic diagrams show volume flow and the required work input for variable working conditions… - Control operation and regulation

In order to achieve a certain required operating condition a control operation is carried out either on the installation, the compressor drive or on the compressor… - Monitoring and diagnosis

Important components of piston compressors are subject to wear which cannot be avoided and which could lead to a shutdown of the compressor with subsequent loss of production entailing high costs as a consequence… - Trends

Development is driven by the continuing growing possibilities of theoretical simulations of those physical processes in compressor intallations, which reduce their life expectancy and efficiency…

- [0] Küttner, K. H.: Kolbenmaschinen. B.G. Teubner, Stuttgart 2009[1] Kleinert, H.-J.; Wächter, K.: Grundlagen der Kolbenmaschinen. Abschnitt 1 in: Taschenbuch Maschinenbau, Band 5, Kolbenmaschinen, Strömungsmaschinen, Berlin 1989, Verlag Technik[2] Dittrich, E. et al.: Technische Thermodynamik. Abschnitt 4 in: Taschenbuch Maschinenbau, Band 2, Berlin 1985, Verlag Technik

[3] Kleinert, H. J.; Will, G.: Kolbenverdichter. Abschnitt 1.5 in: Taschenbuch Maschinenbau, Band 5, Berlin 1989, Verlag Technik

[4] Poling, E. B.; Prausnitz, J. M.; O’Connell, J. P.: The Properties of Gases and Liquids. 5. Aufl., 2000, McGraw-Hill Professional, 2000

[5] DIN EN 1012-1: 2011-02: Kompressoren und Vakuumpumpen–Sicherheitsanforderungen-Teil 1: Kompressoren; Deutsche Fassung EN 1012-1:1:2010

[6] American Petroleum Institute: Reciprocating Compressors for Petroleum, Chemical, and Gas Industry Services. API Standard 618, a) Fourth Edition, Washington, D.C. 20 005, June 1995 b) fifth Edition, Washington, D.C.

[7] Frenkel, M. I.: Kolbenverdichter: Theorie, Konstruktion und Projektierung, Berlin, VEB Verlag Technik, 1969

[8] Pohlenz, W.: Bauteile für Pumpen, Berlin 1983, Verlag Volk und Wissen

[9] Böswirth, L.: Strömung und Ventilplattenbewegung in Kolbenverdichterventilen. Verbesserter und erweiterter Nachdruck 2002. Wien: Eigenverlag, 1994

[10] Blaha, J.; Smid, V.: Allgemeine Klassifikation der Anwendungsgebiete von Pumpen und Verdichtern. Maschinenmarkt, Würzburg 87 (1981), 69, S. 1419

[11] Wärmeaustauscher, Vulkanverlag, 2. Ausgabe 1994

[12] Standards of the tubular exchanger manufactures association, New York 1988 (7. edition)

[13] Schwaigerer, S.: Festigkeitsberechnung im Dampfkessel-, Behälter- und Rohrleitungsbau. Springer-Verlag, Berlin, 4. Auflage 1990

[14] AD-Merkblätter. Hrsg.: VdTÜV e.V. Essen, Beuth-Verlag GmbH, Berlin, Wien, Zürich

[15] Machu, G.: Calculating reliable impact valve velocity by mapping instantaneous flow in a reciprocating compressor. Paper. Gas Machinery Conference GMRC USA, 2004

[16] DIN ISO 6621 Kolbenringe

[17] Feistel, N.: Beitrag zum Betriebsverhalten trocken laufender Dichtsysteme zur Abdichtung der Arbeitsräume von Kreuzkopfkompressoren, Dissertation Universität Erlangen, 2002

[18] Kriegel, G.: Beitrag zur Berechnung des Radialverschleißes von Trockenlaufkolbenringen. Dissertation, Technische Universität Dresden, 1977

[19] Meltzer, G.: Einführung in die technische Diagnostik. www.mlu.mw.tu-dresden.de

[20] Samland, G.: Kolbenkompressorventile aus der Sicht eines Kompressor- und Ventilherstellers. In Industriepumpen und Kompressoren, Vulkanverlag Essen, 2002, Heft 1

[21] van Lier, L. et al.: The Impact of an API 618 4th of 5th Edition Analysis on the Design of a Very Large Hydrogen Compressor. Proceedings of 7th EFRC Conference 2010, S. 133 ff.

[22] Spiegel, B. et al.: Next Generation Valve Technology for High Speed Compressors. Proceedings of 7th EFRC Conference 2010, S. 327 ff.

[23] Aigner, R. et al.: Development of a Stepless Flow Control System. Proceedings of 7th EFRC Conference 2010, S. 120 ff.

[24] Traversari, R. et al.: Thermo-fluid-dynamic design of reciprocating Compressor Cylinders by Fluid Structure Interaction Software simulation. Proceedings of 7th EFRC Conference 2010, S. 286 ff.

[25] Lindner-Silvester, T., Hold, C.: The BCD packing ring – a new high-performance design. Proceedings of 7th EFRC Conference 2010, S. 113 ff.

[26] Koop, L.G.M.; Duinefeld, P. N.: Development of innovative sensor and method for direct measurement of rider wear. Proceedings of 7th EFRC Conference 2010, S. 105 ff.

[27] Roman, G.; Heumesser, T.: Piston rod vibrations of excessive amplitudes on a CO2 compressor – Simulation, Measurements and Reengineering to solve the effect. Proceedings of 7th EFRC Conference 2010, S. 75 ff.

[28] Eberle, K.; Cyca, M.: Design Challenges for Reciprocating Compressors in Specialty Gas Services. Proceedings of 7th EFRC Conference 2010, S. 259 ff.

[29] Cyklis, P. et al.: Challenges in use of analogue of the four-pole transfer matrix in the 1D time domain pulsation simulations. Proceedings of 7th EFRC Conference 2010, S. 271 ff.

[30] Nored, M. et al.: Gas Passage System Pulsation Analysis for Modern Reciprocating Compressors. Proceedings of 7th EFRC Conference 2010, S. 299 ff.

[31] Brun, K.; Kurz, R.: Dynamic Pressure Losses in Piping Systems. Proceedings of 7th EFRC Conference 2010, S. 142 ff.

[32] Lenz, J.: Development and application of vibration improvements. Proceedings of 7th EFRC Conference 2010, S. 309 ff.

[33] Grote, K.-H.; Feldhusen, J.: Dubbel – Taschenbuch für den Maschinenbau, 23. Aufl., Berlin Heidelberg, Springer-Verlag, 2011

[34] Nickol, J.; Hefele, H.: Neuer Zylinder für CO-Hochdruck 700 bar in geschrumpfter Ausführung. 1. EFRC-Conference, Dresden 1999, Verlag und Bildarchiv W.H. Faragallah, Sulzbach

[35] Huschenbett, M.; Will, G.: Thermodynamic Simulation of Reciprocating Compressors to enable Diagnostic based on Measured Temperature and Pressure. 4. EFRC-Conference, Antwerp, 2005

[36] Hastings, M.; Schrijver, J.: Improved monitoring strategy developed in close cooperation between the machine manufacturer, instrument supplier and end-user gives positive results. 3th EFRC-Conference, Wien 2003

[37] Spiegel, Artner, D.; Steinrück, P.: System for direct wear monitoring of rider rings in reciprocating compressors. 3.EFRC-Conference, Wien 2003

[38] Flade, G.: Weiterentwicklung der Berechnungsmethoden für Kolbenverdichterventile auf der Basis zweidimensionaler Strömungssimulation. Dissertation Technische Universität Dresden, 2006