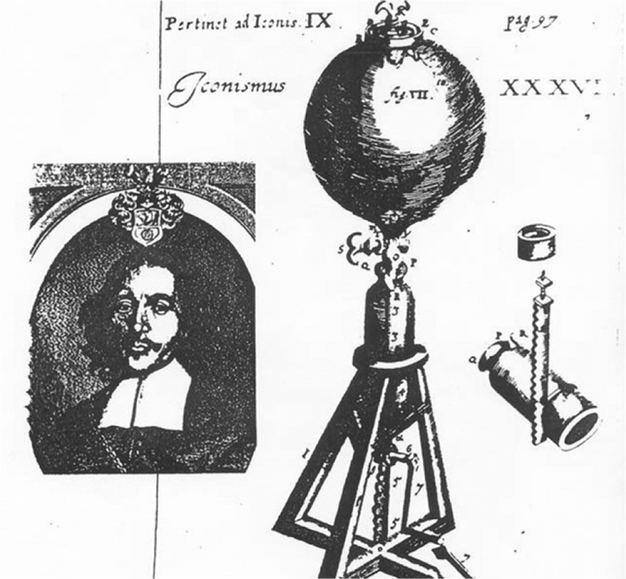

Pressure increase of air by applying mechanical work had already been done in early times. In the Middle Ages hand operated bellows were used in metal foundries. Otto von Guericke developed in 1641 an air pump to create vacuum, which was the basis for the spectacular test with the Magdeburg hemispheres, see Figure 3.1. Both designs can be taken as the predecessor to today’s piston compressors.

History and development

Figure 3.1: Magdeburg hemispheres (1641)

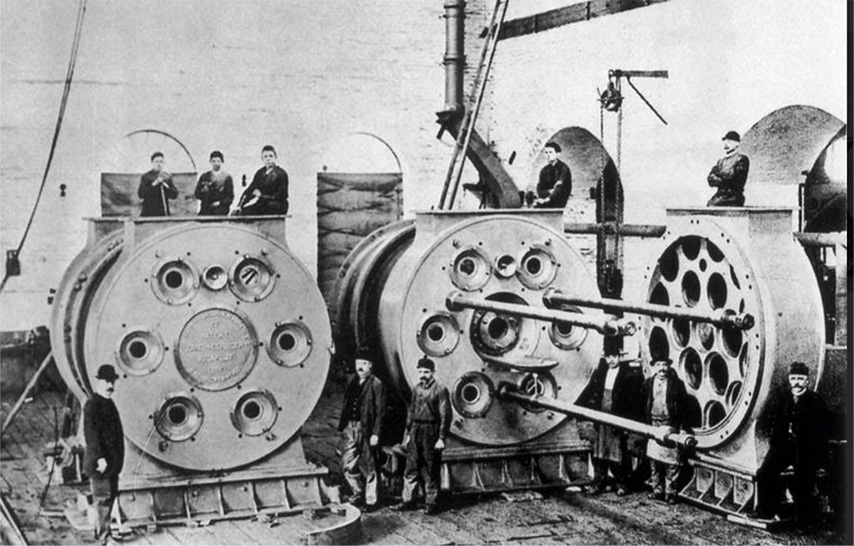

Following the development of the steam engines the first industrially manufactured piston machine, the manufacture of piston compressors was initiated. The similarity in design is shown in the picture below, see Figure 3.2.

Figure 3.2: The first industrially manufactured piston compressor

The first industrially manufactured single-stage compressors were used for the pumping of air with pressures of 3 to 7 bar, applied in iron foundries and in mining.

At the end of the 19th century, the generation and liquefaction of technical gases required multistage compressors for higher pressures. Process development in the chemical industry led to compressors with ever-increasing throughputs and discharge pressures.

The use of piston compressors for the generation of compressed air as energy supply and as part of refrigeration plants paved the way to mass production of small compressors in the lower pressure range, see Figure 3.3.

Figure 3.3: Refrigeration plant

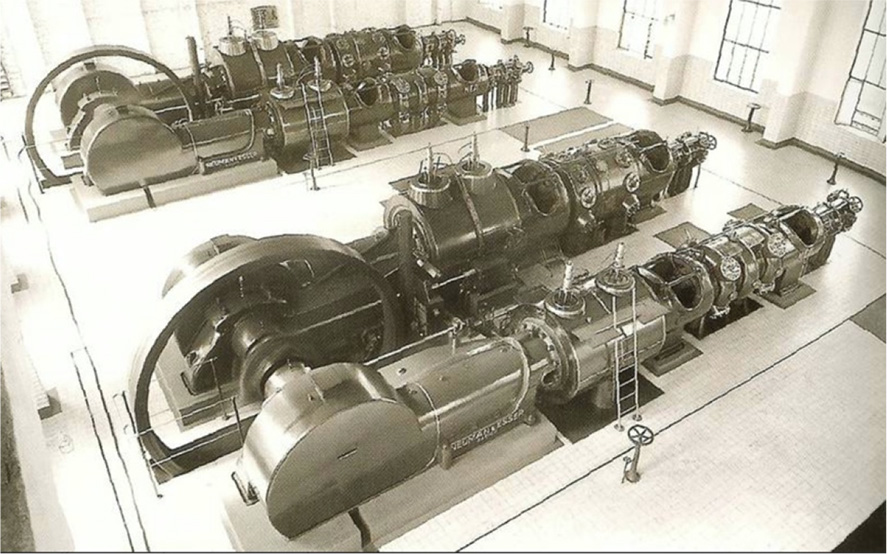

As steam engines were designed for higher inlet temperatures without cylinder lubrication due to the lack of adequate oils, also non-lubricated compressors appeared on the market at the beginning of the 1930s. These were mainly used in breweries, where completely oil-free and odourless air was required, see Figure 3.4.

Figure 3.4: Horizontal air compressors, powered by steam engines

Nowadays the design of non-lubricated compressors for pressures up to 30 MPa is well established and is a precondition for the use of piston compressors in many process plants. In particular, the development of more and more wear resistant ring material and self-adjusting sealing elements have contributed to that effect.