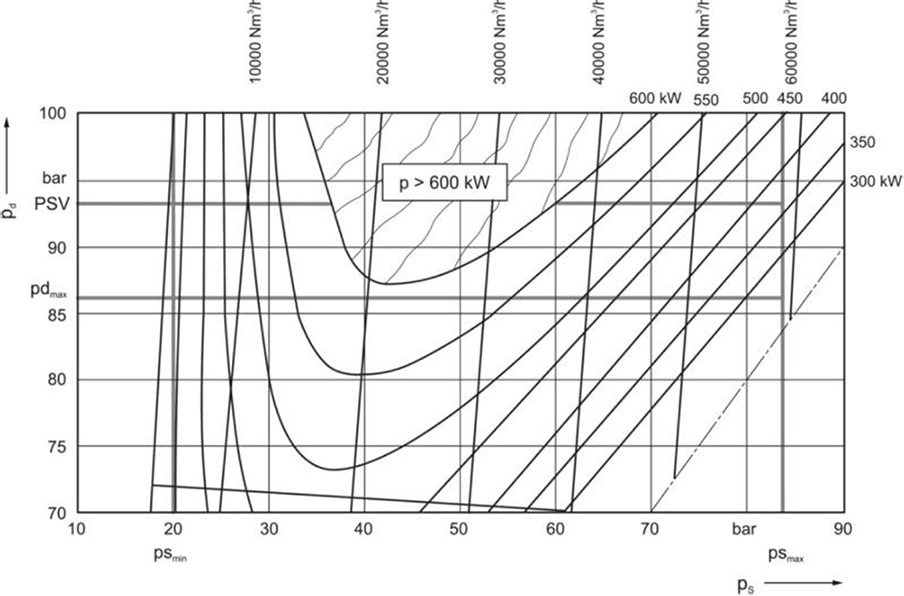

Characteristic diagrams show the volume flow and the required work input for variable working conditions. They can be obtained either by measurement or by approximation calculations. The curves can be given either with absolute values or with values related to working conditions of volume flow, discharge pressure and power requirement. Alternatively, characteristic values such as pressure ratio, volumetric efficiency and energy efficiency are being used.

As a first example, we look at a single-stage compressor with variations of suction and discharge pressures. For a natural gas compressor in boxer design the manufacturer supplies the diagram as shown (operating map), see Figure 6.1.