Important components of piston compressors are subject to wear which cannot be avoided, and which could lead to a shutdown of the compressor with subsequent loss of production entailing high costs as a consequence.

The manufacturer therefore has to design those components which undergo the highest wear – such as compressor valves, piston rings and pressure packings– in such a way, that service free maintenance intervals of one to three years (8 000 to 25 000 running hours) can be achieved.

The user has to continuously monitor the proper functioning of the compressor in order to avoid breakdowns and personal damage. Knowledge about the present state of wear and its trend makes it possible to plan the necessary service and shutdown times of the plant in advance.

The control system of the compressor installation has to include a condition monitoring system which checks the interstage pressures and temperatures (also perhaps the power input and mechanical vibrations) and compares them within given limits. It can then, if necessary, shut down the plant.

Important compressor stations with a high danger potential are more often fitted with an extensive control and monitoring system. The following examples demonstrate the logical and technical structure of such systems.

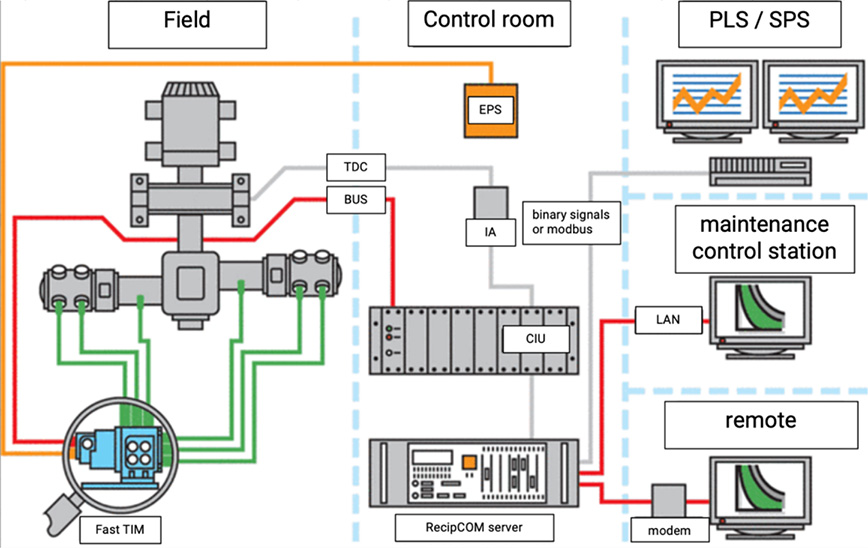

The system works in three areas: In the explosion proof field, area sensors are fitted, which convert pressures, temperature and vibrations into electric signals, see Figure 6.8.

Figure 6.8: Control and monitoring systems for compressor stations [0]

They are then converted into digital information. Via a data bus these information are passed on to the non-explosion proof control area to the Compressor Interface Unit (CIU). The control and condition monitoring system then visualize the results of measurement and analysis and gives warnings. Via internet links, clients can also visualise the results in a third remote area that can again be used for systems configuration.

The most difficult task for the direct control system is the early warning system. A safe diagnosis of specific malfunctions is possible, if they cause characteristic changes in measurement data, which can be directly related to the malfunction.

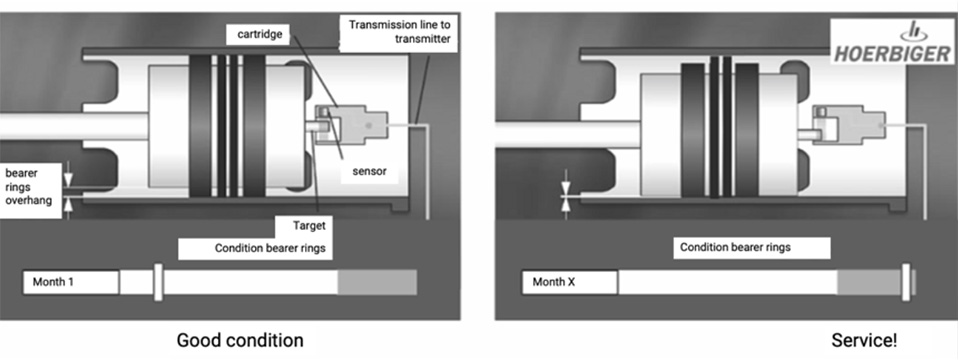

For example, the wear of rider rings in horizontal cylinders can be measured by the displacement of the piston in relation to a sensor in the cylinder [37].

Figure 6.9: Measurement of the wear of rider rings in horizontal cylinders [0]

Unfortunately, there are not enough reliable and economically useable sensors for the direct measurement of wear and stress of moving components.

Therefore, a diagnosis system is necessary, which analyses the information already obtained on interstage pressures and temperatures and a minimum of additional data (for example valve chamber temperatures, cylinder pressures, run out of the piston rod). From these data, it then deducts an information on the wear condition of the compressor.

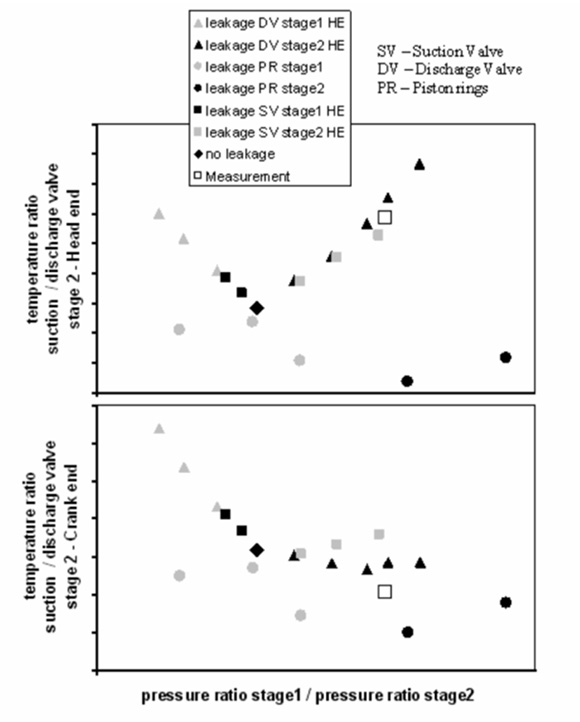

In order to solve this problem, the blurred classification (fuzzy logic) can be used, see Figure 6.10.

Figure 6.10: Blurred classification (fuzzy logic) [0]

From the total of measurement data, a characteristic vector is established, which is then compared with the characteristic vectors of various stages of damage (wear conditions). For the practical use of this method, the determination of characteristic vectors of all classes of damage is required (learning phase).

In most cases only experts (often via tele-monitoring at the manufacturer) are capable of giving information on the condition of the machine, based on the changes of measurement data over time (this includes data on mechanical vibrations and p,V-diagrams). An automatic diagnosis of a fault condition is only possible if there is a repetition of the failure pattern [36].

A general solution to the diagnosis problem presupposes the theoretical simulation of the behaviour pattern of compressor installations of any design, which can also model the effects of wear. A toolbox [35] for the modular simulation of the flow path of the gas through the compressor makes a reproduction possible, which is close to reality of the time depending thermodynamic processes in multistage compressors.