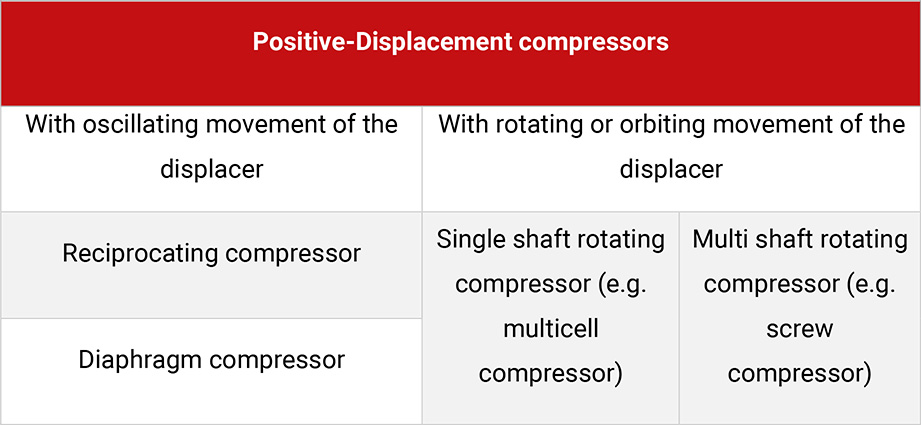

Reciprocating compressors work according to the positive displacement principle. The periodic change in volume of the working chamber is carried out by a piston which moves on a straight line. The change of volume can also be carried out via an oscillating diaphragm (diaphragm compressor), see Table 2.3.

Reciprocating compressors

Table 2.3: Comparison between different positive-displacement compressors

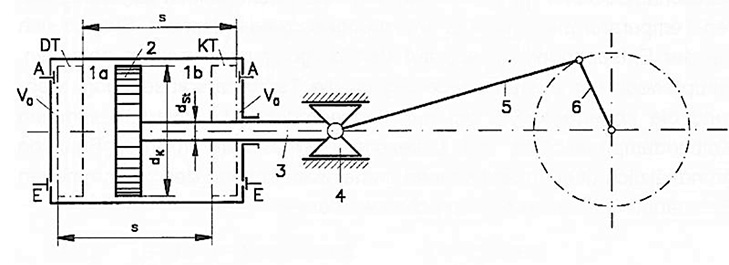

Besides the oscillating compressors there are compressors with rotating or orbiting displacement (rotors or revolving pistons) which are called rotating piston compressors. The piston (2) with the diameter dk moves inside the cylinder 1 between the two end positions (top dead center DT and bottom dead center KT), with the stroke s, see Figure 2.2. If there are working chambers on both sides of the piston (1a, 1b), the compressor is called double-acting, as opposed to single-acting.

Figure 2.2: Schematic structure of a double-acting reciprocating compressor [0]

The difference between the largest and the smallest volume of the working chamber is called the piston displacement . The smallest volume is called the clearance volume . The gas to be compressed enters the working chamber and leaves it after the compression via the compressor valves (suction valves E and discharge valves A)

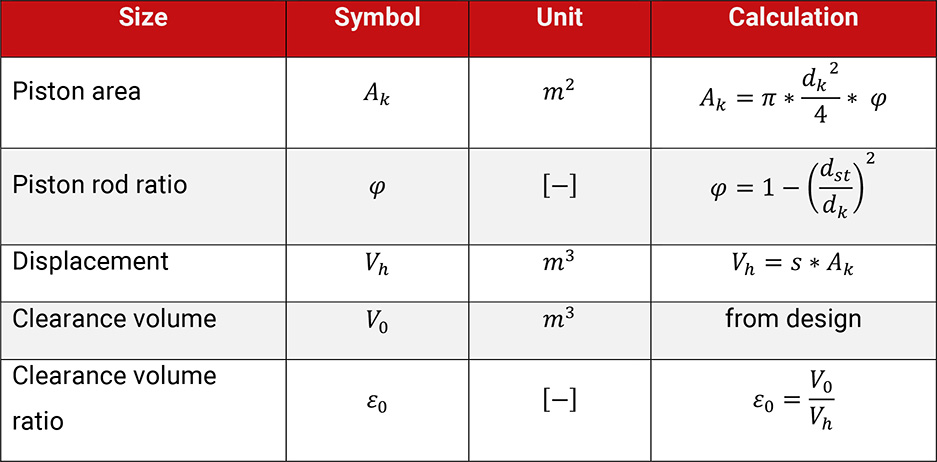

Table 2.4: Important parameters to describe a reciprocating compressor

The oscillating movement of the piston is created via the crank mechanism (consisting of piston rod 3, crosshead 4, connecting rod 5 and crank 6). The geometric parameters and the calculation of them are showed in Table 2.4.

Piston compressors for higher pressure or higher compression ratio are designed as multistage compressors. That is a design with several working cylinders arranged and working in series. The displacement within a stage can be split up into several cylinders working in parallel.